As soon as the bottle is filled and capped, the countdown begins. Single layer PET bottles, though they appear to be impermeable, are slightly porous, and over time CO2 escapes and/or O2 permeates through the material. How fast this process happens determines the "shelf-life".

In today’s fast-paced environment, it can take less than an hour from preform to case packer. Products show up on the grocer’s shelf within a few short days. Bottles that under perform with regards to shelf-life can affect a consumer’s experience, impact future sales and ultimately damage the brand image. With the trend for bottle self-manufacture by brand owners and increased emphasis on light weighting, bottle shelf-life properties are increasingly impacted by the production process. Faster production processes with lighter bottles dictate a new approach towards shelf-life management. One such approach is the M-RULE® container performance model for analyzing shelf-life in PET beverage bottles. The M-RULE model is notable because of the speed of the tests, and the reproducibility of the result, all at a significantly lower cost than traditional methods.

When a bottle is designed, considerable effort is put into optimizing the mechanical and aesthetic properties of the container. For a given bottle design, the shelf-life is primarily determined by the surface area and effective thickness of the package sidewall, which in turn determines the weight of that package. Because cost is a key objective, the package weight is usually the minimum needed to achieve the targeted shelf-life. In theory, if you get everything right and every bottle is produced by a uniform process, then every bottle should exhibit the same shelf-life properties. In reality, this is not the case. Variations that affect the bottle blowing process continually occur. Differences in preform moisture content and temperature, material properties, blow molder anomalies, plant environmental changes, operator experience... to name a few, all impact material distribution and affect sidewall thickness, the property that is so crucial to shelf-life performance.

Why is this so critical now? In the past, variations in the blowing process were masked by heavy sidewalls and extra material. Bottles were over-engineered, and their shelf-life exceeded the minimum targets. As a result, minor variations in material distribution had no impact on product quality. Light weight bottles are the game changer. The processing window on a light weight bottle is very narrow, and the target shelf-life is achieved only in bottles with optimal material distribution. Minor deviations in material distribution and wall thickness that normally would have little impact in the past, now can result in significant production that does not meet shelf-life specifications.

With the reality of variability in the process inputs, the only way to ensure consistency in shelf-life is to tightly control, monitor and continually adjust the blowing process. And, by pro-actively managing variations in material distribution and thickness, shelf-life performance can be managed as part of this process. However, even with the various process monitoring techniques in practice today, shelf-life is one aspect that is not typically incorporated into the routine process monitoring and response programs. This is because, until recently, monitoring shelf-life properties on the production floor has not been a simple matter.

Traditional shelf-life testing methods can take as long as 8–24 weeks, hardly practical when timely and accurate data is necessary to make process related decisions. Furthermore, these tests require intensive laboratory preparation prior to testing, continual monitoring and attention during the test, and have limitations that can result in testing inaccuracies. Variations in bottle to bottle dosing, fill level, temperature control of the testing environment and so forth affect test results, making it difficult to predict shelf-life with confidence using these methods. "There are a lot of things you can do to compromise a CO2 test.... It is sometimes like throwing dice" claims a bottle development engineer at a major beverage producer.

Container Science Inc, Atlanta GA, offers a very tangible solution to the shelf-life dilemma with its M-RULE container performance model for analyzing shelf-life in PET beverage bottles. Commercially available since 2002, the model has been validated repeatedly by brand owners, converters and technology developers. This model overcomes the variability of traditional testing by providing a means to evaluate bottles using standardized data, testing and environmental conditions, resulting in a very repeatable method. And, with results available within seconds, it overcomes the critical issue of timeliness.

The M-RULE container performance model for beverages is a web based predictive tool. It operates by integrating the fundamentals of permeation with critically evaluated physical data for the materials in a given package (bottle and closure) and other pertinent data affecting the permeability of a container, such as temperature and pressure.

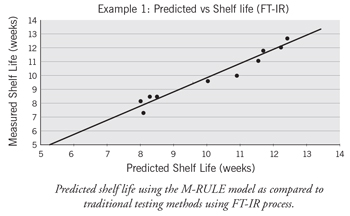

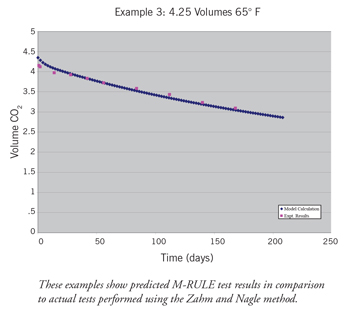

The M-RULE model takes into account a host of parameters and bottle attributes as part of the shelf-life determination, such as surface area, material distribution (wall thickness), base design, filling conditions, storage and distribution conditions, etc. The impact of material properties such as construction of the sidewall, resin, orientation of the material, crystallinity, the modulus of the resin and scavenging activity can also be tested. The model simultaneously predicts CO2, O2, N2, and H2O permeation based on first-principles calculation of the diffusion and solubility of these gasses, along with the impact of stress, temperature, crystallinity and modulus on these parameters. For this reason, the model can accurately predict bottle performance under a wide range of conditions. Package-specific performance is determined by applying bottle parameters such as surface area, weight, base design, finish, volume and filling conditions. All calculations include the impact of the closure on package performance. Below are three examples of the model’s predictive capability vs. two different traditional test methods.

When specific bottle/package details are entered into the model, a very accurate determination of shelf-life can be made. This is accomplished without the influence of many of the issues that compromise the results of traditional tests such as:

With the M-RULE model these items are non-issues. Every test is performed to the exact same conditions and testing protocol. Any difference in test results is a direct reflection of the shelf-life performance of the container, not the test conditions or testing procedures.

A major advantage of the model, is that it can be used to determine the performance of a given bottle design under a myriad of conditions or scenarios. How will this bottle perform at 30oC vs. 22oC? Would the performance change if a different brand or type of material was used? How is shelf-life affected if the bottle was light-weighted by 0.5 gram or 1 gram?

Scenarios like these can easily be evaluated, and shelf-life performance identified well before any investment is made in bottle production.

The M-RULE model is currently relied upon by major brand owners all over the world to critically analyze designs for proper shelf-life performance characteristic prior to prototyping and manufacture. Because of its comprehensive nature, it allows designers to test and optimize designs before committing to actual production. It is also a valuable tool for determining the effect of minor changes to a bottle due to light weighting and how those changes will affect the shelf-life performance. Further, it can be used for assessing whether a package is over or under engineered and how it will perform for any defined set of filling, storage or distribution conditions.

The M-RULE model has been tested in a number of scenarios and results are identical to traditional real-time tests, within the inherent error limits of those tests. Where the M-RULE model excels is in the speed of the test and reproducibility of the results.

These validation tests confirm the accuracy of the M-RULE Model in predicting CO2 Shelf-Life. Other validation results show similar performance for oxygen ingress, nitrogen loss, and water loss.

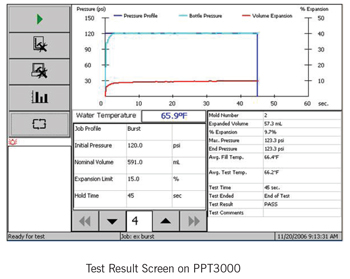

The M-RULE model offers a viable alternative to traditional testing, for both research and design laboratories and production quality testing. Realizing the potential for M-RULE on the plant floor, Agr International, through an exclusive agreement with Container Science, Inc., has incorporated the M-RULE container performance model into the PPT3000TM Packaging Pressure Tester, a device that is routinely used by PET bottle makers to verify quality and performance of bottles on a regular basis during production. By incorporating the M-Rule model into this device, it is now possible to bring shelf-life testing to the plant floor and take advantage of the accuracy, reliability and precision of the model, and most importantly the availability of immediate results.

With this capability in the PPT3000, it is possible to get quick and accurate feedback on material utilization and shelf-life performance of newly blown bottles at the time and point of production.

The PPT3000 with M-RULE works on the premise that if every bottle were identical, the shelf-life would equally be identical. However, if one parameter changes then the shelf-life would also change. Given that the wall thickness is the most critical parameter for shelf-life, the wall thickness parameter is used as the variable. Any change in wall thickness is reflected in the shelf-life results.

During a test, the bottle is pressurized to a pre-defined level. The volume expansion and corresponding material thickness is captured when pressurization reaches the appropriate level. The average material thickness on a bottle under test is automatically entered into an embedded version of M-RULE model created for that bottle. The model is seamlessly run with every PPT3000 test. With all other parameters in the M-RULE unchanged, variations in volume expansion and the related thickness values reflect changes in shelf-life. If thickness distribution changes over the course of bottle production, routine tests with the PPT3000 will identify any corresponding changes in shelf-life.

Different bottle designs are handled by the creation of unique "jobs" created by Agr using the M-RULE laboratory version. These contain information on bottle design, material type, surface area, finish, closure and other input data required to determine shelf-life in the M-RULE model. These are stored on board the PPT3000 and can be quickly called upon to test different bottle types produced within a plant or as production changes.

The PPT3000 with M-RULE offers a practical method for testing shelf-life that takes less than 60 seconds per bottle, requires no special preparation and can be performed in the laboratory or on the production floor. This makes it possible to routinely sample and test production bottles on a regular basis for proper shelf-life. The real advantage of this system is that it can be used as a production tool to verify that bottles meet shelf-life standards, and most importantly, identify compromising issues when they are happening, not days or weeks later. Test results are displayed on the PPT3000 system’s user interface in the form of shelf-life and percent material utilization. This information can also be exported to a laboratory or plant data system. In the event that shelf-life targets are not per specification, intervention can occur immediately to correct the problem and get the process back on track.

Changes in shelf-life performance can occur quickly on today’s high-speed production lines. Whether process changes have a minimal or a major effect on shelf-life is only a guessing game unless regular testing is performed. Having visibility of the effect of these variables on shelf-life at the blow molder (point when bottles are blown) gives you better ability to control shelf-life for your finished product.

There is real value of doing shelf-life analysis near the line or in the bottle production lab. By doing so, you get an immediate sampling of container (shelf-life) performance which is the direct result of current plant conditions and process variations at the time.

The feedback gained can be used in multiple ways including:

With regular testing, and the continual monitoring of shelf-life performance of the ongoing production run, it is possible to pro-actively manage your blowmolder to maintain optimal utilization and as a result, maximize shelf-life for your production and ultimately maintain the high standards of your brand.