Proper pressure testing of PET containers is an essential part of a smooth filling process and favourable downstream performance of carbonated soft drinks (CSD) and other pressure products. Whether we realize it or not, all PET containers used for pressure products are being pressure tested, both as they are filled in high-speed counter-pressure filling machines and in the distribution channels as they experience varying ambient temperature conditions. Relying on the filling equipment and downstream events of a container's life cycle to verify container performance can be very costly and have undesirable implications on brand confidence. For this reason, state-of-the-art container manufacturers have adopted pressure testing protocols that simulate all of the conditions experienced by the container during the filling process and beyond. This paper will discuss the pressurized environments that a PET carbonated beverage is subjected to and the test methods used to ensure that commercial quality containers are produced.

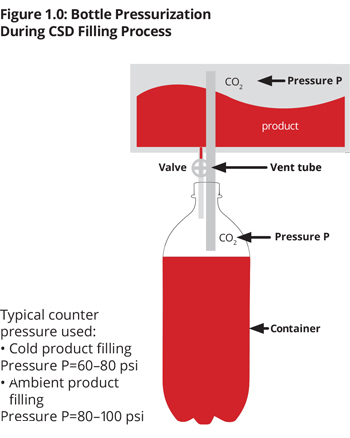

The typical filling process for a PET carbonated beverage container uses a counter-pressure technique. When the empty container is presented to the filling station, it is sealed and quickly charged with CO2. The CO2 located above the carbonated product in a holding bowl as well as in the container are pressurized higher than the desired product carbonation level to prevent the dissolved CO2 in the product from coming out of solution during filling. Typical counter pressures range from 60–100 psi for cold or ambient filling conditions. Gravity is used to transfer the carbonated product from the bowl into the container, and after the filling process is complete, pressure is relieved from the container. A schematic of this technique can be seen in Figure 1.0.

Of particular note in the filling process is the speed of initial pressurization of the PET container, by far the most important step as it relates to the ongoing performance of the container. The initial pressurization found in normal filling machines occurs in approximately 500 milliseconds, as the ambient air in the container is replaced with CO2.

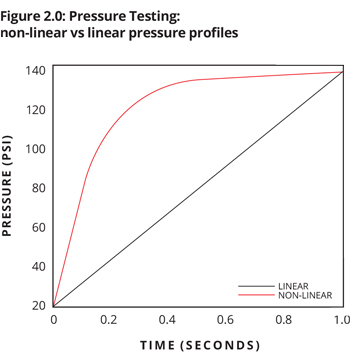

This rapid, non-linear pressurization in PET containers can trigger brittle failures, especially in the base. Excess amorphous material that remains in the base of the container after the blowing process creates a region, with high concentrations of stress, between the oriented and amorphous material. The material in this region is brittle and can fracture easily when the container is pressurized. Many of these early failures occur well below the pressure level used in the counter-pressure filling process. Conversely, pressure testing containers with slow initial pressurization characteristics is not sufficient to identify when the blowing process is making containers that will not survive this first step of the filling process (figure 2.0).

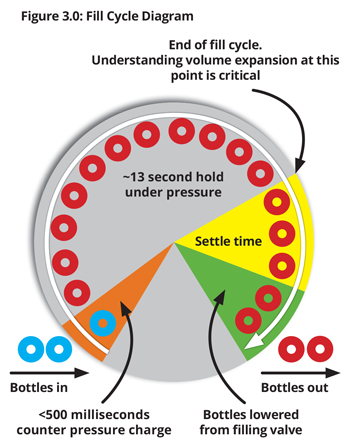

A container that survives the initial rapid pressurization still may not provide acceptable performance. After the counter-pressure has been applied, the container is subjected to a pressure hold for approximately 13 seconds (figure 3.0). Understanding volume expansion behaviour of the container during this hold time provides an important data point about how the container will react throughout the commercial life cycle. A container with a weak overall structure or lower levels of material orientation may expand beyond acceptable levels, causing thinning of the wall thickness, faster loss of carbonation and a higher risk for side wall failures. To ensure that the filled container will ultimately perform for the consumer, a quality pressure testing method must include the pressure hold at a value that simulates the real-world experience of the bottle.

The ultimate material properties of a finished PET container are the cumulative result of multiple factors including the time and temperature profiles for heating the preform, along with the stretching and blowing profiles in the formation of the container itself. A change in any of these variables will affect many factors, including the pressure at which the container will experience an unrecoverable yield or deformation. The natural frequency and potential impact of these processing changes drive the need to regularly pressure test containers to determine how a given production run will perform under filling and down-stream conditions.

For over 25 years, PET containers have been pressure tested with the intent of understanding how well a container will perform under real-world filling, storage, transportation, shelf-life and consumer-use conditions.

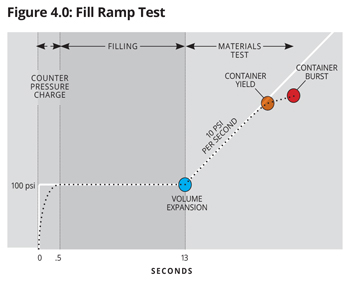

When PET, as a material, is tested using a tensile tester, a stretching force is applied to determine the amount of force required to reach the yield point (where material is permanently deformed) and is continued until failure (point where the material stops stretching and breaks). With a container, this can be equated to the application of internal pressure expanding the container volume and stretching the material to the point where the PET yields, and then a continuation of pressurization to container failure (burst). Yield and burst are the two key material failure modes experienced by a PET bottle. This simple ramp approach is acceptable for use only after the 13 second hold spoken of earlier.

To simulate actual conditions, a complex test is warranted that subjects the container to the same abrupt, non-linear pressure dynamic (counter-pressures) seen in the filling process, then held at actual filling pressures for the appropriate filling time, and then subjected to a continuously increasing pressure ramp to identify the container yield point and ultimate failure. Testing PET containers in this manner provides the manufacturer with the information required to understand how the containers will perform in the filling operation and throughout the commercial life cycle.

An example of a testing system that provides the capabilities to simulate the complex pressure profile of the filling operation is the Agr PPT3000TM. The PPT3000 accurately represents the counter-pressure filling simulation by providing a precise pressure profile that simulates a true filling environment.

This pressure profile has been dubbed the "Fill Ramp", where the container is subjected to an abrupt, ~500 millisecond non-linear pressurization, up to the test pressure hold level (60–100psi). It is held at that test pressure for 13 seconds, and then subjected to a pressure ramp increase of 10 psi/sec, leading to the identification of the yield pressure and ultimate burst pressure. The "Fill Ramp" pressure profile (figure 4.0) shows the change in pressure vs. time for the test and how the different segments of the test correlate with the filling cycle.

With the trend toward high-speed, combined blow-fill operations and the propagation of ultra-lightweight PET containers, it has become increasingly imperative to identify and correct blow molding problems before loss-of-pressure failures occur downstream in the filler, in the warehouse or through retail channels.

The only way to truly understand the downstream performance characteristics of PET carbonated beverage containers is by reproducing the abrupt, non-linear pressurization that a container experiences during the filling process. Routine pressure testing that follows the pressure profiles applied by the filling machine, in combination with the monitoring of material properties, form the basis for a sound testing program that will ensure optimal container performance, both in the production/filler environment as well as throughout the commercial life cycle.

The Agr PPT3000 is the only pressure testing system currently available that truly simulates the filling process and, ultimately, the downstream conditions.