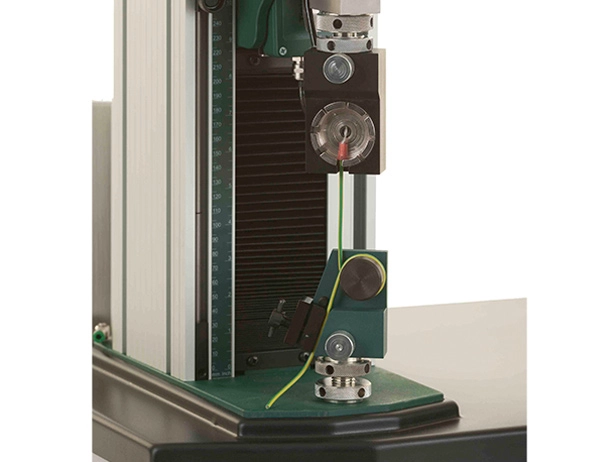

A model known as a universal testing machine (UTM) is created to evaluate a material's strength and product performance by measuring its mechanical characteristics, such as tensile, flexural, compressive, and shear. This apparatus tests final components as well as raw materials, metals, polymers, fabrics, rubbers, adhesives, and food. A variety of tests, including those for tensile strength, shear strength, compressive strength, flexural strength, puncture and burst resistance, tear strength, peel strength, and melt flow, are available with this sort of multipurpose equipment.

A specimen is fastened during a tensile test and is then continuously loaded with tensile forces, stretching and eventually tearing the specimen apart. To ensure that the data is transferable between labs, these tests are carried out according to an internationally recognized standard process and calculation of findings. Depending on the standard, the rate of loading can be applied as a constant rate of extension, constant rate of strain, or constant rate of load.

All of the tests are designed and implemented in accordance with key international testing standards including ISO, ASTM, EN, and various other industrial standards. The introduction of different tensile strength types for different sectors in accordance with their respective qualities ST series, L series, and Horizon software.